Vac Series

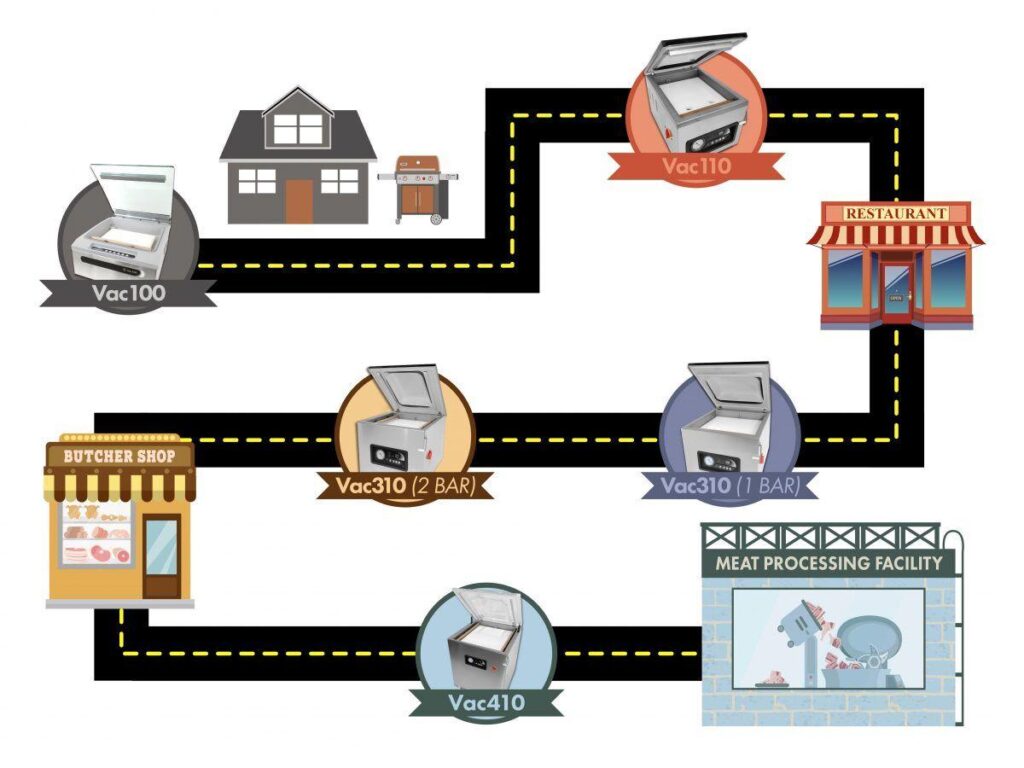

VacSeries, chamber vacuum sealers were perfected and are supported here in the USA for use on your countertop at home or larger units to be used commercially. We offer a 6mm to 10mm wide seal on our variety of toolless seal bars. Varying chamber sizes and depths for multiple applications. Retort capability on both our Vac100 and Vac110 makes these a versatile and essential piece of equipment. Simple digital controls on our Vac110, 310, and 410! Looking for preset options? Our Vac100 has simple programmable controls to help with expediting the process and standardizing your packaging.

Vac100 – Chamber Vacuum Sealer – Arkansas Food Equipment

Vac110 – Chamber Vacuum Sealer – Arkansas Food Equipment

Vac310 (1 Bar) – Chamber Vacuum Sealer – Arkansas Food Equipment

Vac310 (2 Bar) – Chamber Vacuum Sealer – Arkansas Food Equipment

Vac410 – Chamber Vacuum Sealer – Arkansas Food Equipment

What Is A Chamber Vacuum Sealer?

Initially the pressure around us and inside the chamber are exactly identical (14.7 psi at sea level). Vacuum is created inside the chamber which in turn creates an airtight seal. Depending on the vacuum pump quality, up to 99.8% of the air is then removed from the chamber and vacuum pouch. Once all the air is extracted from the chamber, the vacuum pump shuts off and the bag is sealed.

Up to this point it will appear as though no air has been removed from the vacuum pouch. The pressure inside the pouch is equal to the pressure in the chamber. After the bag is fully sealed off, a valve will open to reintroduce air back in. The process will continue until pressure is equal to the environment outside the chamber. During these few seconds is when the bag will tighten up around the product. Finally, the vacuum sealed look will be observed in this final process.

MASON JAR SEALING

Use with any size mason jar to seal it and preserve your jams, pickles, and more!

LIQUIDS

including soups, wines, marination, general moisture content from meats, and more! External vacuum sealers commonly break due to liquids being sucked up into the machine

RETORT POUCH CANNING

also known as retort processing or conventional canning. Heating food to a certain temperature to kill off all pathogenic microorganisms and lengthening storage life span.

EXPEDITED PICKLING

by taking all of the air out of the cucumber while replacing it with pickling juice

RAPIDLY INFUSE

alcohols, extracts, and more!